SOUND ISOLATION AND DAMPENING CLIP

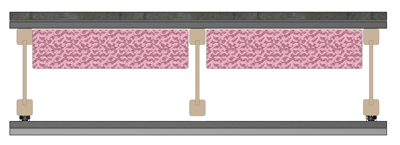

The ClarkDietrich Sound Clip™ (CDSC) is used in conjunction with 18mil (25ga) 7/8" deep drywall furring channel. It is used to fasten gypsum wallboard in various wall and floor-ceiling applications, while simultaneously providing acoustical separation. This significantly reduces the amount of airborne sound filtering from room to room. The ClarkDietrich Sound Clip increases the STC ratings in most assemblies while reducing sound transfer.

- Ideal for use in multi-family dwelling, hotels, theaters and hospitals

- Used in conjunction with 7/8" 25 ga Furring Channel with a total standoff from stud of 1-5/8"

- UL fire rated for most common assemblies

- Complies to UL 263 test standards. See full list of UL® design assemblies in UL R19331

- Rubber ASTM standards: D2240, D2000, D412, D395, D573, D1149, D2137

- Maximum spacing 48" o.c. (laterally) x 24"o.c. (vertically)

- Maximum acoustical design load is 36 lbs.

- SOUND TESTING FOR TYPE X & TYPE C BOARDS

PRODUCT DATA & ORDERING INFORMATION

| Thickness: | 43mil (18ga) | |

| Yield Strength: | 33ksi | |

| Coating: | G60 | |

| Dimensions: | 3" x 1-1/4" (Clip only) | |

| Packaging: | (100) pieces per box |

ATTACHMENT TO FRAMING STUDS:

- Fasteners for Wood Framing Studs:

#8 x 2-1/2" minimum size coarse thread screw

(Recommended #12 or #10 x 2-1/2" hex head) - Fasteners for Steel Framing Studs:

#8 x 1-1/2" minimum size fine thread screw

(Recommended #12 or #10 x 1-5/8" hex head) - DO NOT attach CDSC to framing members with nails.

(Only use approved screws)

COMPLIES TO UL 263 TEST STANDARDS. SEE FULL LIST OF UL® DESIGN ASSEMBLIES IN UL R19331

WALL SOUND ASSEMBLIES ARE CERTIFIED BY WESTERN ELECTRO-ACOUSTICAL LABORATORIES

FLOOR SOUND ASSEMBLIES ARE CERTIFIED BY INTERTEK BUILDING & CONSTRUCTION (B&C)

NVLAP ACCREDITED FOR ASTM E90 & E413, ISO CERTIFIED

SEE SOUND TEST REPORTS (IN BELOW LINKS) FOR DETAILED REQUIREMENTS OF CONSTRUCTION OF ASSEMBLY.

CDSC SOUND ASSEMBLIES ON METAL STUD FRAMING

| Fire Rating | UL Assembly | Wall Framing |

Stud Spacing |

Wall Board (Side1/Side2) | Insulation |

STC Rating |

OITC Rating |

Test Report |

|---|---|---|---|---|---|---|---|---|

| 3-5/8" ProSTUD 20 (33mil) | 24" o.c. | (1) Layer / (1) Layer - 5/8" Type C | R-19 | 60 | TL18-291 | |||

| 3-5/8" ProSTUD 20 (33mil) | 24" o.c. | (1) Layers / (2) Layers - 5/8" Type C | R-19 | 62 | TL18-292 | |||

| 3-5/8" ProSTUD 20 (33mil) | 24" o.c. | (2) Layers / (2) Layers - 5/8" Type C | R-19 | 63 | TL18-293 | |||

| 3-5/8" ProSTUD 25 (15mil) | 16" o.c. | (1) Layer / (1) Layer - 5/8" Type X | R-11 | 56 | TL18-199 | |||

| 3-5/8" ProSTUD 25 (15mil) | 16" o.c. | (1) Layer / (2) Layers - 5/8" Type X | R-11 | 60 | TL18-197 | |||

| 3-5/8" ProSTUD 25 (15mil) | 16" o.c. | (2) Layers / (2) Layers - 5/8" Type X | R-11 | 62 | TL18-194 | |||

|

2 Hr |

U411 | 2-1/2" ProSTUD 25 (15mil) | 24"o.c. | (2) Layers / (2) Layers - 5/8" Type X | R-13 | 62 | 48 | L3173.08-113-11-R0 |

| 3/4 Hr | U423 | 3-1/2" Structural Stud (33mil) | 24"o.c. | (1) Layers / (1) Layers - 1/2" Type C | R-19 | 53 | 37 | L3173.10-113-11-R0 |

| 1 Hr | U423 | 3-1/2" Structural Stud (33mil) | 24"o.c. | (1) Layers / (1) Layers - 1/2" Type X | R-19 | 55 | 38 | L3173.12-113-11-R0 |

| 1-1/2 Hr | U423 | 3-1/2" Structural Stud (33mil) | 24"o.c. | (2) Layers / (2) Layers - 1/2" Type C | R-19 | 62 | 48 | L3173.11-113-11-R0 |

| 2 Hr | U423 | 3-1/2" Structural Stud (33mil) | 24"o.c. | (2) Layers / (2) Layers - 5/8" Type X | R-19 | 63 | 50 | L3173.13-113-11-R0 |

| 1 Hr | U465 | 3-5/8" ProSTUD 20 (18mil) | 24"o.c. | (1) Layers / (1) Layers - 5/8" Type X | None | 45 | 29 | L3173.03-113-11-R0 |

| 1 Hr | U465 | 3-5/8" ProSTUD 20 (18mil) | 24"o.c. | (1) Layers / (1) Layers - 5/8" Type X | Mineral Wool | 53 | 36 | L3173.04-113-11-R0 |

| 1 Hr | U465 | 3-5/8" ProSTUD 20 (18mil) | 24"o.c. | (1) Layers / (1) Layers - 5/8" Type X | R-13 | 53 | 37 | L3173.05-113-11-R0 |

| 1 Hr | U493 | (2) 2-1/2" ProSTUD 25 (15mil) - ChaseWall | 24"o.c. | (1) Layers / (1) Layers - 5/8" Type X | R-13 Both Sides | 60 | 44 | L3173.06-113-11-R0 |

| 2 Hr | U493 | (2) 2-1/2" ProSTUD 25 (15mil) - ChaseWall | 24"o.c. | (2) Layers / (2) Layers - 5/8" Type X | R-13 Both Sides | 67 | 53 | L3173.07-113-11-R0 |

| 1 HR | V438 | 2-1/2" ProSTUD 25 (15mil) | 24"o.c. | (1) Layers / (1) Layers - 1/2" Type C | R-13 | 49 | 34 | L3173.09-113-11-R0 |

| 2 Hr | V438 |

1-5/8" ProSTUD 25 (15mil) |

24"o.c. | (2) Layers / (2) Layers - 1/2" Type C | 2-3/4" Fiberglass | 59 | 42 | L3173.14-113-11-R0 |

| 3 Hr | V438 | 1-5/8" ProSTUD 25 (15mil) | 24"o.c. | (3) Layers / (3) Layers - 1/2" Type C | 2-3/4" Fiberglass | 63 | 49 | L3173.15-113-11-R0 |

| 4 Hr | V438 | 1-5/8" ProSTUD 25 (15mil) | 24"o.c. | (4) Layers / (4) Layers - 1/2" Type C | 2-3/4" Fiberglass | 66 | 53 | L3173.16-113-11-R0 |

CDSC SOUND ASSEMBLIES ON 2X4 WOOD STUDS

| Fire Rating | UL Assembly | Wall Framing | Stud Spacing | Wall Board (Side1/Side2) | Insul | STC Rating | OITC Rating | Test Report |

|---|---|---|---|---|---|---|---|---|

| 2x4 Wood Studs | 16"o.c. | (1) Layer / (1) Layer - 5/8" Type X | R-19 | 53 | TL18-201 | |||

| 2x4 Wood Studs | 16"o.c. | (1) Layer / (1) Layer - 5/8" Type C | R-19 | 60 | TL18-288 | |||

| 2x4 Wood Studs | 16"o.c. | (1) Layer / (2) Layer - 5/8" Type X | R-19 | 57 | TL18-204 | |||

| 2x4 Wood Studs | 16"o.c. | (1) Layer / (2) Layer - 5/8" Type C | R-19 | 61 | TL18-289 | |||

| 2x4 Wood Studs | 16"o.c. | (2) Layer / (2) Layer - 5/8" Type X | R-19 | 61 | TL18-205 | |||

| 2x4 Wood Studs | 16"o.c. | (2) Layer / (2) Layer - 5/8" Type C | R-19 | 62 | TL18-290 | |||

| 2 Hr | U301 | 2x4 Wood Studs | 16"o,c, | (2) Layer / (2) Layer - 5/8" Type X | R-13 | 60 | 47 | L3173.01-113-R0 |

| 1 HR | U309 | 2x4 Wood Studs | 24"o.c. | (1) Layer / (1) Layer - 5/8" Type X | R-19 | 53 | 37 | L3173.17-113-R0 |

| 1 HR | U311 | 2x4 Wood Studs | 24"o.c. | (1) Layer / (1) Layers - 5/8" Type C | R-19 | 55 | 39 | L3173.18-113-R0 |

| 1 HR | U340 | 2x4 Wood Studs - Chase Wall | 12"o.c. Staggered | (1) Layer / (1) Layers - 5/8" Type X | R-19 | 57 | 43 | L3173.21-113-R0 |

| 1 HR | U341 | 2x4 Wood Studs - Chase Wall | 24"o.c. | (1) Layer / (1) Layer - 5/8" Type X | R-19 | 60 | 45 | L3173.20-113-R0 |

| 1 HR | U344 | 2x4 Wood Studs | 24"o.c. | (1) Layer 5/8" Type X / (1) Layer 5/8" Plywood + 5/8" Type X | R-19 | 57 | 41 | L3173.19-113-R0 |

| 1 HR | U356 | 2x4 Wood Studs | 16"o.c. | 7/16" Plywood / (1) Layers - 5/8" Type X | R-13 | 51 | 34 | L3173.02-113-R0 |

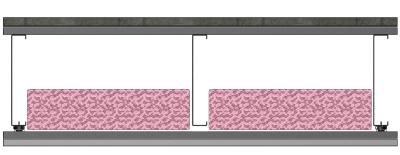

10" TRADEREADY® STEEL JOISTS W/LEVELROCK (UL DESIGN NO. G551)

| Material Description | STC | IIC | Test Report | |

|---|---|---|---|---|

|

Carpet w/ Pad | 55 | 80 | J4775.02 |

| Ceramic w/ NobleSeal® | 57 | 50 | J4775.06 | |

| Shaw Engineered Wood | 54 | 50 | J4775.03 | |

| Shaw Como Vinyl 12mm | 55 | 48 | J4775.04 | |

| Shaw Expo Vinyl 6mm | 54 | 47 | J4775.05 | |

|

Baseline System (See full material list here) UL Design No. G551 Ceiling: (1) layer 5/8" Type C |

54 | 43 | J4775.01 |

|

+(1) Gypsum C-Core Layer with: Shaw Expo Vinyl 6mm on top of the floor UL Design No. G551 |

58 | 51 | J4775.07 |

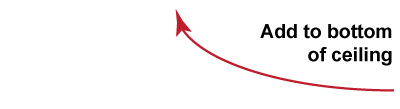

16" WOOD OPEN WEB TRUSS (OWT) W/LEVELROCK (UL DESIGN NO. UL-L521)

With (1) layer 5/8" Type C attached to hat channel

| Material Description | STC | IIC | Test Report | |

|---|---|---|---|---|

|

Carpet w/ Pad | 59 | 79 | J4777.02 |

| Ceramic w/ NobleSeal® | 59 | 53 | J4777.06 | |

| Shaw Engineered Wood | 58 | 53 | J4777.03 | |

| Shaw Como Vinyl 12mm | 58 | 51 | J4777.04 | |

| Shaw Expo Vinyl 6mm | 58 | 51 | J4777.05 | |

|

Baseline System (Nothing on top of LevelRock) UL Design No. UL-L521 Ceiling: (1) layer 5/8" Type C |

58 | 50 | J4777.01 |

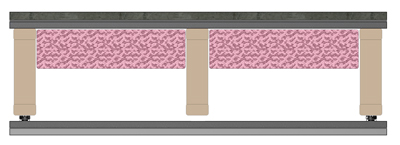

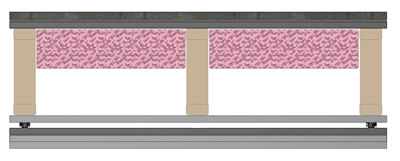

16" WOOD OPEN WEB TRUSS (OWT) W/LEVELROCK (UL DESIGN NO. UL-M510)

With (1) layer 5/8" Type C on the bottom of the joist + (2) Layers 5/8" Type C attached to hat channel

| Material Description | STC | IIC | Test Report | |

|---|---|---|---|---|

|

Carpet w/ Pad | 58 | 75 | J4778.02 |

| Ceramic w/ NobleSeal® | 57 | 51 | J4778.06 | |

| Shaw Engineered Wood | 58 | 50 | J4778.03 | |

| Shaw Como Vinyl 12mm | 58 | 49 | J4778.04 | |

| Shaw Expo Vinyl 6mm | 58 | 50 | J4778.05 | |

|

Baseline System (Nothing on top of LevelRock) UL Design No. UL-M510 Ceiling: (1) layer 5/8" Type C +(2) layers 5/8" Type C |

58 | 50 | J4778.01 |

12" WOOD TRUSS JOIST (TJI) W/LEVELROCK (UL DESIGN NO. UL-L518)

With (2) layers 1/2" Type C attached to hat channel

| Material Description | STC | IIC | Test Report | |

|---|---|---|---|---|

|

Carpet w/ Pad | 62 | 84 | J4776.03 |

| Ceramic w/ NobleSeal® | 63 | 56 | J4776.07 | |

| Shaw Engineered Wood | 62 | 56 | J4776.04 | |

| Shaw Como Vinyl 12mm | 62 | 54 | J4776.05 | |

| Shaw Expo Vinyl 6mm | 61 | 53 | J4776.06 | |

|

Baseline System (Nothing on top of LevelRock) UL Design No. UL-L518 Ceiling: (2) layers 1/2" Type C |

62 | 50 | J4776.02 |

8" CONCRETE SLAB W/ (1) LAYER GYPSUM CEILING

(1) layer 5/8" Type X attached to hat channel

| Material Description | STC / Test Report | IIC / Test Report |

|---|---|---|

| Carpet Tiles | 62 / RAL-TL21-030 | 61 / RAL-IN21-009 |

| Vinyl Planks 7mm | 63 / RAL-TL21-031 | 61 / RAL-IN21-010 |

| Baseline System (Nothing on top of 8" Concrete) Ceiling: R-6.7 unfaced fiberglass insulation + (1) layer 5/8" Type X |

62 / RAL-TL21-032 | 60 / RAL-IN21-011 |

8" CONCRETE SLAB W/ (2) LAYERS GYPSUM CEILING

(2) layers 5/8" Type X attached to hat channel

| Material Description | STC / Test Report | IIC / Test Report |

|---|---|---|

| Carpet Tiles | 63 / RAL-TL21-029 | 61 / RAL-IN21-008 |

| Vinyl Planks 7mm | 63 / RAL-TL21-020 | 64 / RAL-IN21-003 |

| Baseline System (Nothing on top of 8" Concrete) Ceiling: R-6.7 unfaced fiberglass insulation + (2) layers 5/8" Type X |

63 / RAL-TL21-027 | 64 / RAL-IN21-006 |

THE INFORMATION PROVIDED HEREIN IS AN ASSEMBLY SUMMARY.

PLEASE SEE TEST REPORTS FOR COMPLETE ASSEMBLY DETAILS.

WALL TESTS NOTES:

The test was performed in accordance with ASTM E 90-09 (2016), Standard Test Method for Laboratory Measurement of Airborne Sound Transmission Loss of Building Partitions and ASTM E2235-04 (2012), Standard Test Method for Determination of Decay Rates for Use in Sound Insulation Test Methods.

FLOOR/CEILING TESTS NOTES:

The STC (Sound Transmission Class) and ICC (Impact Insulation Class) ratings were calculated in accordance with ASTM E413 and ASTM E989, respectively.