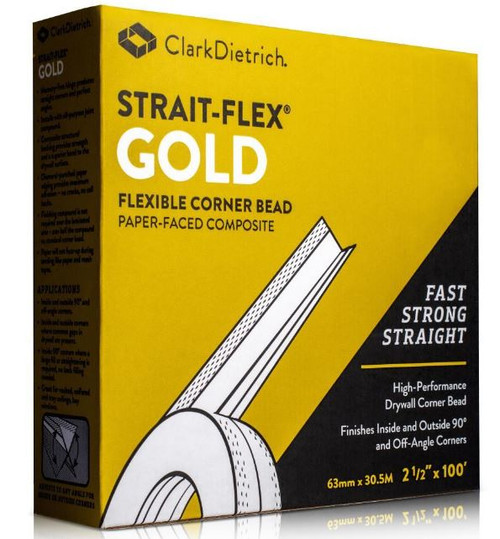

The composite structural backing provides strength for durability and impact resistance. The heavy-weight, diamond punched paper provides maximum adhesion for an even lay-down of the paper edge and reduced edge cracking. Strait-Flex Mid-Flex is packaged in 100 ft. rolls that can be cut to the desired length in the field to minimize scrap loss.

- Memory-free hinge produces straight corners and perfect angles

- Smooth nose provides a square, low profile – drywall knives will not catch, snag or puncture center hinge

- Composite-fiber structural backing provides strength and embeds into compound to provide a superior bond to the drywall surface

- Diamond-punched paper edging provides maximum adhesion – no cracks, no call backs

- Paper surface is pretreated to accept paint, finishing compound is not required over the laminated area – uses the half the compound vs. standard corner bead

- Paper will not fuzz-up during finish sanding like paper and mesh tapes

- Installs with all-purpose joint compound. No special tools or fasteners are needed. Lightweight compound may be used to finish.

Applications:

- Great for vaulted, coffered and tray ceilings, bay windows.

- Outside corners where common gaps in drywall are present.

- Outside corners where a large fill or straightening is required, no back filling needed.

PRODUCT DATA & ORDERING INFORMATION:

| Product code | width (in) | length (ft) | Rolls/Case | Cases/Pallet |

|---|---|---|---|---|

| MF-100 | 3" | 100' | 10 | 24 |

INSTALLATION

Make sure the surfaces of the corner are clean and smooth. Measure corner and subtract 1/2”. (1) For accurate measuring of Strait-Flex® Mid-Flex and less waste, feed roll through slot on top of box. Hook tape measure on the hole below. (2) Fold Mid-Flex in half with the print side facing out. (3) For outside corners, fold more than the desired angle. For inside corners, fold less than desired angle. (4) Most professionals prefer to cut the ends of Mid-Flex at a 45º angle.

(5) Apply a liberal coat of all-purpose joint compound to both sides of the corner with a 4” or 5” taping knife. (6) Press Mid-Flex into the wet compound. Adjust, if necessary, to create a straight line. (7) Wipe down tight with taping knife using a little additional pressure on the outer edges. Let dry completely over several hours or overnight.

(8) Apply a light skim coat of compound to the outer edges of Mid-Flex with a 4” or 5” taping knife. No compound is required over the laminated area of Mid-Flex. Wipe down tight and smooth. Let dry completely over several hours or overnight.

(9) Apply the final coat of joint compound with a 6” or 8” taping knife. Feather the compound beyond previous coat. A very light coat of compound is all that’s needed. Using lightweight compound in this step makes sanding easier. Let dry completely over several hours or overnight.

(10) Sand lightly with 120 grit sandpaper. Mid-Flex will not fuzz-up like paper or mesh tapes.

CODE APPROVALS & PERFORMANCE STANDARDS

- ASTM C1047 Standard Specification for Accessories for Gypsum Wallboard and Gypsum Veneer Base

- SDS Strait-Flex - Paper-Faced Composite For Gold, Mid-Flex 300, Wide-Flex 400, Edge Tape

STORAGE

- All stored materials shall be kept dry. Materials shall be stacked off the ground, supported on a level

platform, and protected from weather and moisture.